Comparison Of Molded Pulp Process

Dry Press

1. Surface Effect

The surface effect of dry press molded pulp products is rough for one side and is relatively smooth for another side. Dry press products are hot-pressed after drying.

2. Materials

Most of dry press molded pulp products are made of corrugated paper or sugarcane. We can make custom colors according to customers’ needs.

Wet Press

1. Surface Effect

The surface effect of wet press molded pulp products is smooth for one side and is net-mesh for another side. Wet press products are hot-pressed without the process of drying.

2. Materials

The material of wet press products mainly is sugarcane, wood pulp, A4 pulp and bamboo pulp. We can make custom colors according to customers’ needs.

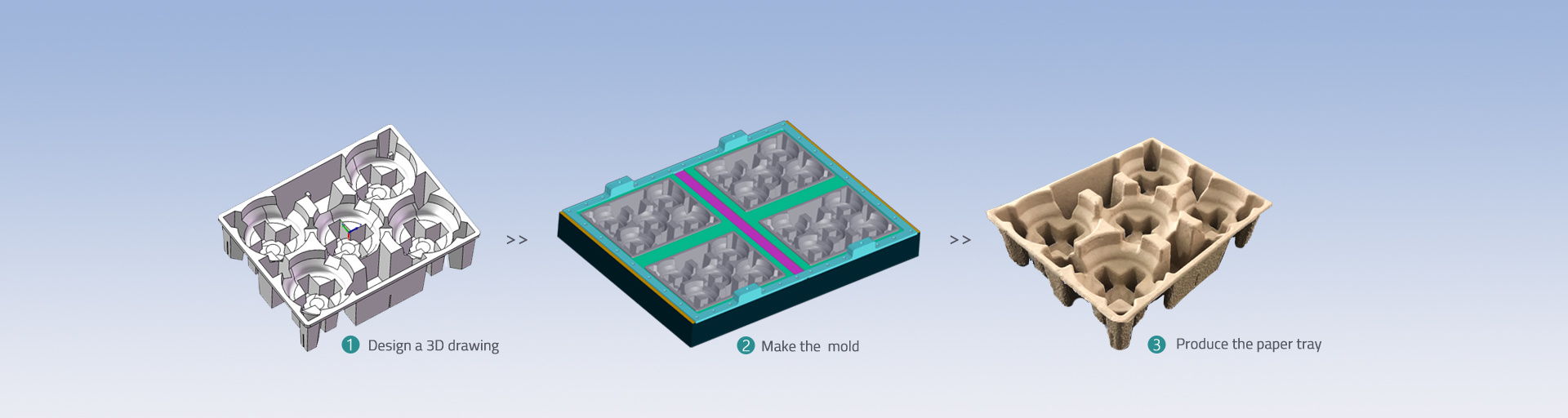

Production Process Of Molded Pulp Products

Raw Materials Selection

Pulping and Mixing

Molding

Drying

Heat Pressing

Cutting

Quality Inspection

Shipment

Biodegradation Test

Day1

Day20

Day40

Day60

Why molded pulp products can be biodegradable?

The main materials of molded pulp products are the following kinds, such as sugarcane pulp, wood pulp, bamboo pulp, corrugated paper, A4 paper, Kraft paper, etc. These materials are rich in plant fibre and without any chemical element, which makes molded pulp products biodegradable in the condition of nature as time goes.

Will molded pulp products be biodegradable indoors?

Most of people are confused about such a question that if we keep our molded pulp products at the warehouse for a long time, whether they will be biodegradable or not. Same as the paper, if molded pulp products are kept in a dry and clean environment indoors, they can be well saved for several years. What we said for their biodegradability is specific for the condition of nature.